As manufacturing becomes increasingly digitized, traditional operational resilience strategies are no longer enough. Cyber resilience — the ability to prepare for, respond to, and recover from cyber threats — is now essential to maintaining uptime, protecting assets, and ensuring business continuity.

This blog explores why cyber resilience is the new operational resilience for manufacturers, and how Atlantic helps companies build a future-ready defense.

The New Reality for Manufacturers

Manufacturers today face a dual challenge: maintaining operational continuity while navigating an increasingly complex digital landscape. From smart factories and IoT-enabled equipment to cloud-based ERP and MES systems, the modern manufacturing environment is deeply interconnected — and vulnerable.

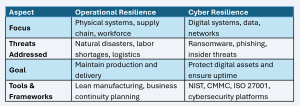

Historically, operational resilience focused on physical infrastructure, supply chain stability, and workforce readiness. But in 2025, cyber threats are just as likely to halt production as a natural disaster or supplier failure. That’s why cyber resilience has emerged as a core pillar of operational strategy.

Operational Resilience vs. Cyber Resilience: What’s the Difference?

While operational resilience keeps the factory floor running, cyber resilience ensures the digital backbone supporting it remains secure and functional.

Why Cyber Resilience Is Now Core to Operational Strategy

Manufacturers are increasingly reliant on digital systems to manage production, logistics, and customer relationships. This shift has expanded the attack surface dramatically:

- IoT devices and sensors are often unsecured entry points.

- Cloud-based ERP and CRM systems store sensitive operational and customer data.

- Remote access tools used by vendors and employees can be exploited.

- Legacy systems may lack modern security protocols.

Cyberattacks like ransomware can shut down entire production lines, delay shipments, and damage customer trust. In some cases, recovery can take weeks — costing millions in lost revenue and regulatory fines.

The Four Pillars of Cyber Resilience for Manufacturers

To build true cyber resilience, manufacturers must invest in four key areas:

1. Threat Detection & Response

Implement real-time monitoring and automated incident response tools to detect and contain threats before they spread.

2. Data Protection & Recovery

Ensure critical data is encrypted, backed up, and recoverable in the event of a breach or system failure.

3. Employee Awareness & Training

Human error is a leading cause of breaches. Regular training helps employees recognize phishing attempts and follow best practices.

4. Third-Party Risk Management

Vendors and partners often have access to internal systems. Vet their security posture and limit access to sensitive data.

The Business Case: ROI of Cyber Resilience

Cyber resilience isn’t just a defensive strategy — it’s a smart investment. Consider:

- Downtime Costs: A single hour of downtime can cost tens of thousands in lost productivity.

- Compliance Requirements: Regulations like CMMC and ISO 27001 demand robust cybersecurity practices.

- Customer Trust: A secure operation builds confidence with clients and partners.

- Cyber Insurance: Many policies require proof of resilience measures to qualify for coverage.

By proactively investing in cyber resilience, manufacturers can reduce risk, avoid costly disruptions, and gain a competitive edge.

How Atlantic Helps Manufacturers Build Cyber Resilience

At Atlantic, we help manufacturing companies assess their digital risk posture and implement tailored solutions that align with their operational goals.

Whether you’re modernizing your infrastructure or preparing for the future, Atlantic is your partner in building a resilient, secure manufacturing operation.

Cyber Resilience Is Operational Resilience

Guess what: cyber resilience is no longer optional — it’s foundational.

As digital systems become more integral to production and delivery, protecting those systems becomes a core part of operational strategy.

Ready to assess your cyber resilience? Contact Atlantic today to schedule a consultation or download our Cybersecurity Guide!

FAQs

What is cyber resilience in manufacturing?

Cyber resilience refers to a manufacturer’s ability to prepare for, respond to, and recover from cyber threats that could disrupt operations.

How does cyber resilience improve operational continuity?

By protecting digital systems and data, cyber resilience ensures that production, logistics, and customer service can continue even during a cyber incident.

What are the top cybersecurity threats to manufacturers?

Ransomware, phishing, insider threats, and vulnerabilities in IoT and legacy systems are among the most common.

About Atlantic, Tomorrow’s Office

Atlantic, Tomorrow’s Office is a leading managed services provider offering managed IT, cybersecurity, office technology, business consulting, and digital transformation solutions. Focusing on helping mid-market businesses optimize their cybersecurity practices, enabling technology and operations, Atlantic delivers end-to-end solutions tailored to the evolving needs of today’s enterprises.

For the latest industry trends and technology insights, visit ATO’s main Blog page.