Manufacturers are achieving 200-400% ROI from AI implementations in predictive maintenance, quality control, and supply chain optimization, with 78% of manufacturing executives already reporting measurable returns from their AI initiatives. As artificial intelligence transforms production environments, measuring AI ROI requires specialized frameworks that account for the unique operational complexities and interdependencies of manufacturing.

With the AI manufacturing market projected to reach $47.88 billion by 2030, companies require proven frameworks to justify investments and scale successful pilots. Every $1 spent on generative AI yields a return of $3.71 across industries, but manufacturing companies require specialized measurement approaches to capture operational benefits and navigate implementation challenges.

Read on to learn proven methodologies for quantifying and maximizing AI investments in manufacturing environments, drawing on industry data that projects the global industrial AI market will reach $153.9 billion by 2030. Whether you’re justifying initial AI adoption or scaling existing digital transformation initiatives, you’ll find actionable frameworks for measuring and improving AI ROI in manufacturing operations.

What You’ll Learn:

- ROI calculation methods tailored for manufacturing AI projects

- Cost structures and benefit quantification in production environments

- Implementation best practices for maximizing AI investment returns

- Measurement frameworks that account for manufacturing-specific variables

Understanding AI ROI in Manufacturing Environments

AI ROI in manufacturing environments differs fundamentally from traditional IT ROI calculations due to operational complexity, equipment interdependencies, and the direct impact on production. Unlike software implementations that primarily affect information workflows, manufacturing AI systems influence physical processes, safety protocols, and production quality, with cascading effects that extend throughout the entire operation.

Manufacturing AI ROI requires specialized measurement approaches because traditional ROI models fail to capture the interconnected nature of production systems. When AI-powered predictive maintenance prevents equipment failure, the benefits extend beyond maintenance cost savings to include avoided downtime, preserved product quality, improved worker safety, and enhanced supply chain continuity. These operational multipliers create substantial value that standard ROI calculations often miss.

This complexity makes manufacturing AI investments particularly attractive to business leaders seeking competitive advantage through digital transformation but also demands more sophisticated measurement frameworks to justify and optimize technology investments.

Manufacturing AI Use Cases and ROI Potential

Translating general ROI concepts into specific manufacturing applications with proven returns reveals where AI technologies deliver the highest measurable value across production environments, quality systems, and supply chain management.

Predictive Maintenance ROI

AI-powered predictive maintenance typically delivers 300-500% ROI through reduced unplanned downtime and optimized maintenance schedules, with machine learning algorithms analyzing sensor data to predict equipment failures before they occur. Manufacturing companies that implement predictive analytics report a 15-20% reduction in maintenance costs and a 10-15% increase in equipment availability.

Quality Control and Inspection ROI

Computer vision systems deliver a 200-300% ROI through defect reduction and faster inspection cycles, replacing manual quality control processes with AI-powered, automated inspections that operate continuously at production line speeds. These AI solutions reduce human error while improving defect detection accuracy and consistency.

Supply Chain and Inventory Optimization ROI

AI demand forecasting and inventory optimization generate 150-250% ROI through reduced carrying costs and stockouts, with AI models analyzing market trends, supplier performance, and production patterns to optimize inventory levels and supply chain management decisions.

Key Points:

- Predictive maintenance delivers the highest ROI (300-500%) through downtime prevention

- Quality control AI provides 200-300% returns via defect reduction and speed improvements

- Supply chain optimization generates 150-250% ROI through inventory and logistics efficiency

These proven use cases provide the context for systematic ROI calculation approaches that capture manufacturing-specific value creation.

ROI Calculation Framework for Manufacturing AI

Building on proven use cases, manufacturers need systematic approaches to quantifying AI value using methodologies that account for production variables, implementation costs, and ongoing operational benefits across multiple measurement timeframes.

Step-by-Step: Manufacturing AI ROI Calculation

When to use this: For manufacturing AI projects requiring financial justification and ongoing performance measurement in production environments.

- Establish baseline metrics: Document current downtime costs, quality rates, energy consumption, labor productivity, and maintenance expenses using existing data sources from production systems and enterprise resource planning platforms.

- Quantify direct benefits: Calculate specific cost reductions, productivity gains, quality improvements, and energy savings based on AI capabilities and proven industry benchmarks from similar implementations.

- Calculate total investment costs: Include hardware, AI software spending, system integration expenses, training costs, and ongoing operational costs for AI system maintenance and optimization.

- Apply ROI formula accounting for manufacturing factors: Use standard ROI calculations while adjusting for production seasonality, equipment lifecycles, and operational variables that affect value realization timelines.

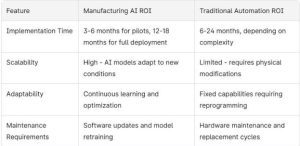

Comparison: Manufacturing AI ROI vs Traditional Automation ROI

A comparison of AI ROI versus traditional automation across key criteria, including implementation time, scalability, adaptability, and maintenance requirements, reveals that AI technologies offer greater flexibility and potential for continuous improvement. However, traditional automation may provide more predictable returns in stable production environments.

Synthesis enables manufacturers to choose between AI and traditional automation based on their specific operational needs and ROI potential, with AI proving most valuable in dynamic environments that require adaptation and optimization.

Even with systematic calculation frameworks, manufacturers encounter common obstacles when implementing and measuring AI ROI, necessitating tailored solutions. To navigate these challenges effectively and unlock the full potential of AI investments, manufacturers should connect with Atlantic.

Our experts provide hands-on support to overcome data quality issues, isolate AI impact accurately, and design phased implementation strategies that deliver measurable ROI. Additionally, for organizations in sectors such as education, document management systems offer significant benefits that enhance data security, accessibility, and operational efficiency.

Partnering with Atlantic ensures you have the guidance and tools needed to turn obstacles into opportunities for achieving operational excellence and sustaining a competitive advantage.

Common Challenges and Solutions in Manufacturing AI ROI

Addressing typical obstacles manufacturers face when implementing and measuring AI ROI ensures accurate value quantification and successful AI transformation across production environments.

Challenge 1: Data Quality and Integration Issues

The Solution: Implement data governance frameworks and invest in sensor infrastructure before AI deployment to ensure AI systems have access to clean, reliable data from production lines and legacy systems.

Poor data quality can reduce AI effectiveness by 40-60%, making upfront data integration investment critical for realizing ROI expectations and enabling successful AI automation across manufacturing operations. For any technology-related issues or questions that could impact your operations, contact our dedicated support team for prompt assistance.

Challenge 2: Difficulty Isolating AI Impact from Other Variables

The Solution: Utilize control groups, A/B testing, and staged rollouts to measure AI-specific contributions while accounting for other operational changes and market trends that may impact production performance.

Manufacturing environments have numerous variables that affect outcomes; systematic measurement approaches ensure accurate ROI attribution, helping business leaders understand the true value of AI creation versus other digital transformation initiatives.

Challenge 3: Long Payback Periods Due to High Implementation Costs

The Solution: Begin with high-impact, quick-win use cases, such as energy optimization, before tackling complex predictive maintenance implementations that require extensive sensor integration and change management.

Phased implementation approaches reduce risk while building internal capabilities and stakeholder confidence, enabling manufacturers to demonstrate measurable value before committing to larger AI investments across enterprise-wide systems.

Overcoming these implementation challenges enables manufacturers to achieve substantial returns from AI technologies and establish sustainable competitive advantages.

Where Should You Start?

Manufacturing AI ROI requires specialized measurement approaches, but it delivers substantial returns when properly implemented and measured. Successful AI transformation depends on systematic frameworks that account for operational complexity and production interdependencies.

To get started:

- Connect with Atlantic to identify high-impact use cases, establish baseline metrics, and calculate potential ROI using a manufacturing-specific framework

- Secure stakeholder alignment and budget approval using proven ROI calculation methods that demonstrate clear business value and competitive advantage potential

- Implement a pilot project with rigorous measurement and scale successful initiatives across manufacturing operations for maximum enterprise value

About Atlantic, Tomorrow’s Office

Atlantic, Tomorrow’s Office is a leading managed services provider offering managed IT, cybersecurity, office technology, business consulting, and digital transformation solutions. Focusing on helping mid-market businesses optimize their cybersecurity practices, enabling technology and operations, Atlantic delivers end-to-end solutions tailored to the evolving needs of today’s enterprises. For more information on Atlantic and its expanded business consulting services, visit www.tomorrowsoffice.com.